PAST

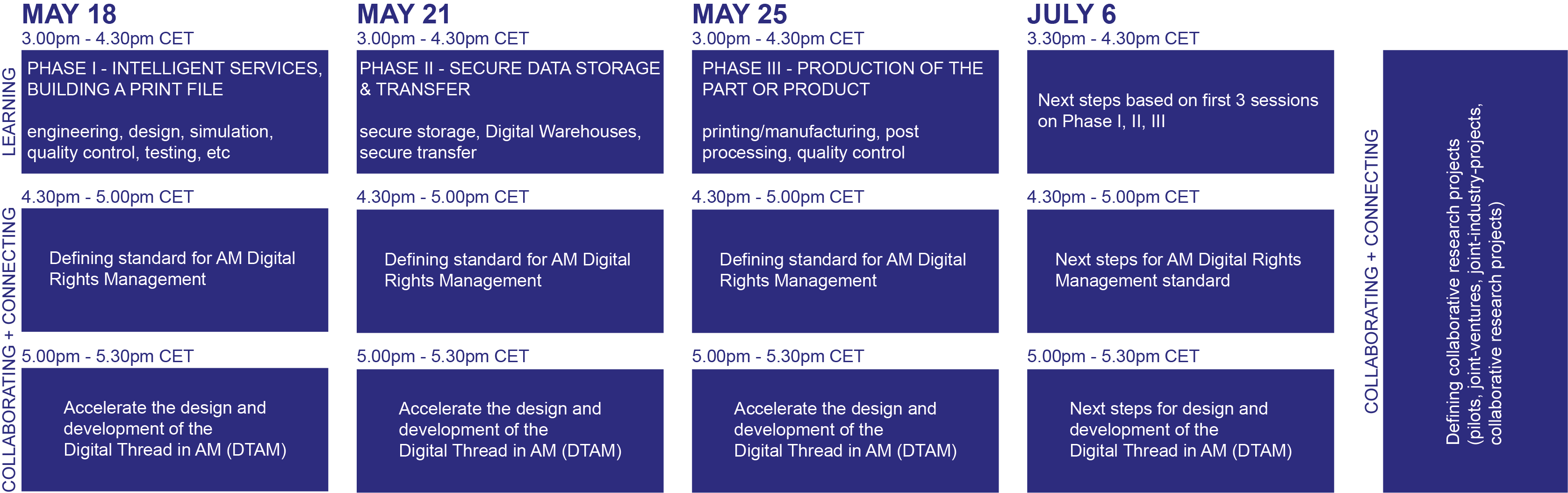

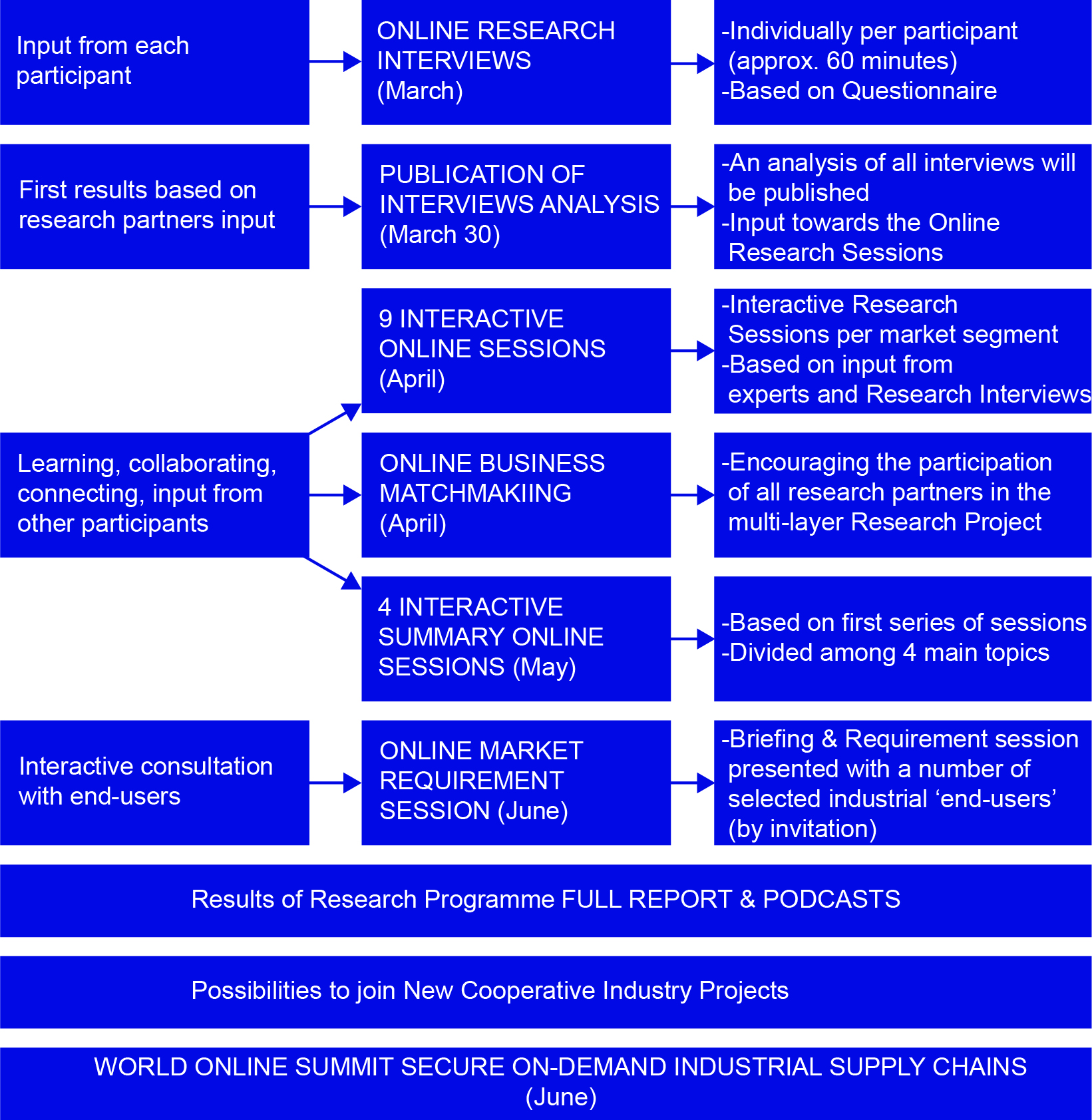

The SDAM Research Project divided Secure Distributed AM Supply Chains into 3 segments (Phase I, Phase II & Phase III) INTERACTIVE ONLINE SESSIONS, BASED ON INPUT FROM EXPERTS AND 150+ RESEARCH INTERVIEWS

NEXT

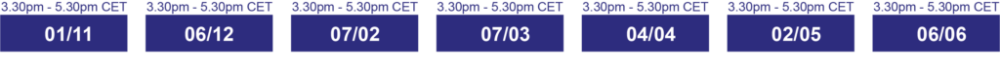

MONTHLY FOLLOW UP SESSIONS BASED ON AGREED COLLABORATIVE PROJECTS

ALL SESSIONS ARE STREAMED WORLDWIDE

ACTUAL LIST OF COLLABORATIVE PROJECTS

- PILOT PROJECT INDUSTRIAL-GRADE SECURE AM FILE SHARING

- DATA INTEGRATION IN INDUSTRIAL AM SUPPLY CHAINS

- DIGITAL SPARE PARTS ONLINE BUSINESS COURSE

- THE FUTURE OF SPARE PARTS IS DIGITAL CONFERENCES @ DSP EUROPE, ESSEN, GERMANY

- THE AM RESEARCH PAVILION @ DSP EUROPE, ESSEN, GERMANY

Registration form SDAM online session

DELIVERABLES (for each participant)

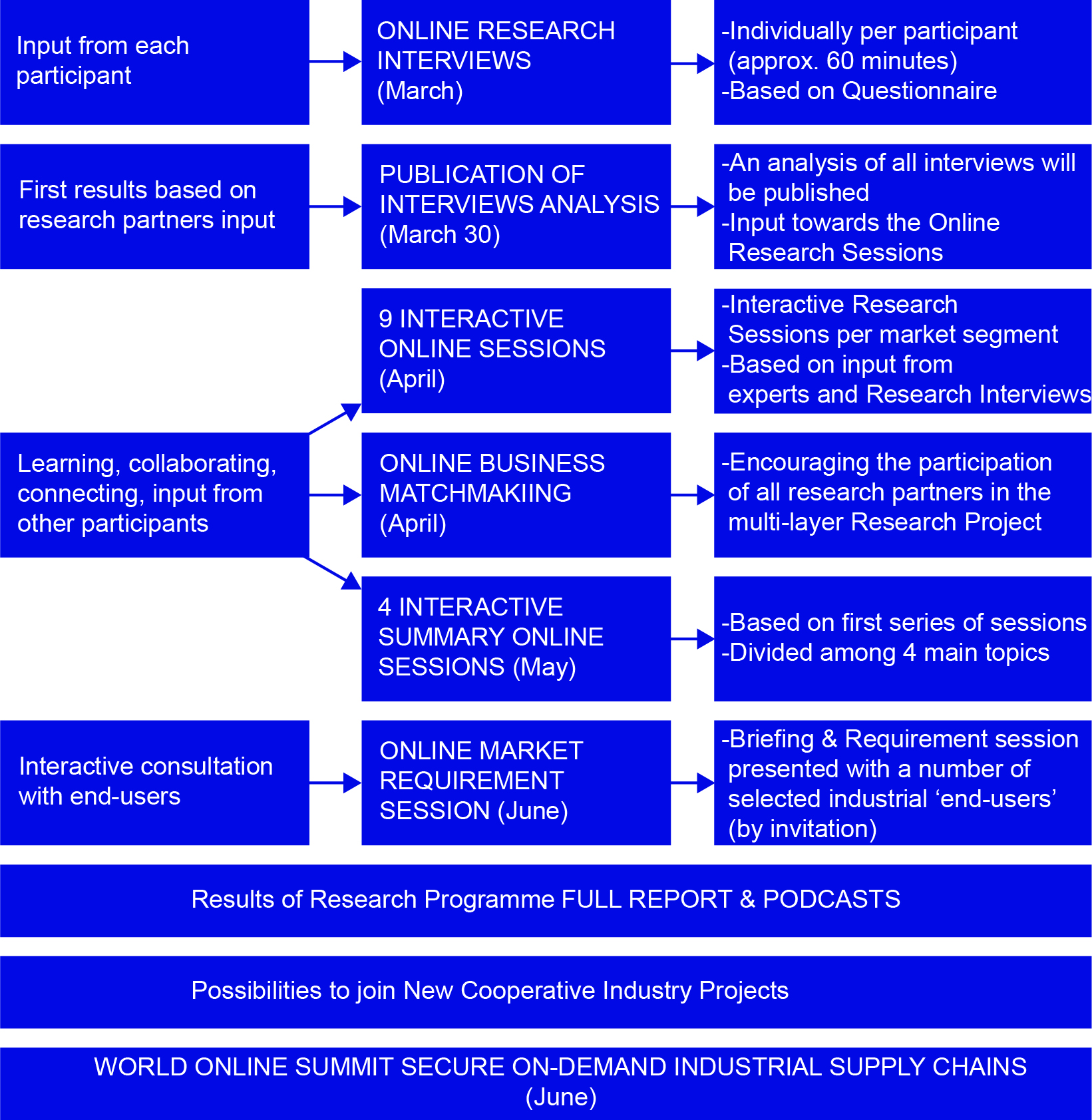

• Research Interview (individual contribution to the Online Research Sessions)

• Participation in Online Research Sessions

• Participation in Online Summary Research Sessions

• Participation in Online Consultation Sessions with Users

• Podcast per Market Segment

• Research Report

Since the start this September, we have already held 140+ Research interviews with suppliers, technology universities and research organisations.

JOIN THESE COMPANIES & ORGANISATIONS

For more information about the SDAM Research Project please contact:

Roelof Kramer | Roelof.Kramer[at]SDAMalliance[dot]com

Or download here the SDAM Research Project Overview

SESSION I.

Secure Data Transfer

Understand challenges and strategies for building a Digital Thread—a single, seamless strand of data that stretches from the initial design to the finished part—can help scale and enhance AM capabilities.

SESSION II.

Blockchain

How could blockchain be utilised in Distributed Manufacturing to support end-to-end Trust: in Ownership (IP & OEM rights), in Quality (Industry-Grade validation & certification) and in Transactions.

SESSION III.

Certification & Quality Assurance

Additive production consists of multiple stages, which must be monitored, assessed and controlled. Qualification and certification standards open a feasible route to product certification.

SESSION IV.

Knowledge & Research

Subject matter experts are putting their knowledge and technology to work for enhancing the security of production chains as Distributed Manufacturing. It’s all about on-demand, local manufacturing.

SESSION V.

Software

The various software systems are building blocks to ensure the successful development of AM processes. The need for collaboration in the production chain is going to be crucial as AM deployment starts to accelerate.

SESSION VI.

3D Printers

Ultimately, most 3D printers are simply special purpose computers, and thus suffer the same potential security risks as any computer, especially when you add networking.

SESSION VII.

Materials

Digital, connected and distributed manufacturing has become a reality with 3D printing, allowing manufacturers to use more efficient and sustainable production methods. Focus should be on the application.

SESSION VIII.

Printer Locations

Secure Distributed AM starts with the secure transfer of data to 3D printers, in all possible locations and on-demand. This is achieved through a seamlessly integrated end-to-end digital solution including relevant manufacturing data.

SESSION IX.

Post Processing

The right digital infrastructure—one that can store, access, and analyse vast amounts of data and interoperate across multiple different machines and processes—is crucial. Machining services information should not be siloed, but integrated.

SESSION I. Secure Data Transfer

Understand challenges and strategies for building a Digital Thread—a single, seamless strand of data that stretches from the initial design to the finished part—can help scale and enhance AM capabilities.SESSION II. Blockchain

How could blockchain be utilised in Distributed Manufacturing to support end-to-end Trust: in Ownership (IP & OEM rights), in Quality (Industry-Grade validation & certification) and in Transactions.

SESSION III. Certification/Quality Assurance

Additive production consists of multiple stages, which must be monitored, assessed and controlled. Qualification and certification standards open a feasible route to product certification.

SESSION IV. Knowledge & Research

Subject matter experts are putting their knowledge and technology to work for enhancing the security of production chains as Distributed Manufacturing. It’s all about on-demand, local manufacturing.

SESSION V. Software

The various software systems are a building block to ensure the successful development of AM processes. The need for collaboration in the production chain is going to be crucial as AM deployment starts to accelerate.

SESSION VI. 3D Printers

Ultimately, most 3D printers are simply special purpose computers, and thus suffer the same potential security risks as any computer, especially when you add networking.

SESSION VII. Materials

Digital, connected and distributed manufacturing has become a reality with 3D printing, allowing manufacturers to use more efficient and sustainable production methods. Focus should be on the application.

SESSION VIII. Printer Locations

Secure Distributed AM starts with the secure transfer of data to 3D printers, in all possible locations and on-demand. This is achieved through a seamlessly integrated end-to-end digital solution including relevant manufacturing data.

SESSION IX. Post Processing

The right digital infrastructure—one that can store, access, and analyse vast amounts of data and interoperate across multiple different machines and processes—is crucial. Machining services information should not be siloed, but integrated.

DELIVERABLES (for each participant)

• Research Interview (individual contribution to the Online Research Sessions)

• Participation in Online Research Sessions

• Participation in Online Summary Research Sessions

• Participation in Online Consultation Sessions with Users

• Podcast per Market Segment

• Research Report

Since the start this September, we have already held 140+ Research interviews with suppliers, technology universities and research organisations.

JOIN THESE COMPANIES & ORGANISATIONS

For more information about the SDAM Research Project please contact:

Roelof Kramer | Roelof.Kramer[at]SDAMalliance[dot]com

Or download here the SDAM Research Project Overview